Switch Lubrication

A significant debate in the keyboard community revolves around the preference for switch feel or sound in keycap sets. There is no superiority between the two; both are essential aspects of custom keyboards. And since we are discussing feel and sound, it inevitably leads us to a crucial topic: switches. It is well known that switches are the primary factors that influence keyboard feel and sound. Currently, the mainstream aesthetic seems to lean towards switches that have been lubricated or are from thinner factory-lubed batches. These switches produce a quieter and more solid sound. On the other hand, some users do not prefer switches that are unlubricated and may describe them as "pingy" or "loose." When they hear typing sounds from keyboards with unlubricated switches, they might subconsciously assume that the keyboard is subpar. In my opinion, the issue lies with the switches themselves. If we divide the sound into ten parts, switches alone contribute to seven or even more. Therefore, how to lubricate switches has become a common concern. How should they be lubricated, and which parts should be lubricated? In this post, I will share my experiences and preferences regarding switch lubrication. If you have differing opinions, please feel free to raise them for discussion.

Please note that this post focuses specifically on MX mechanical switches and does not cover other types such as optical switches or BOX switches.

1. Preparing Switch Lubrication Tools

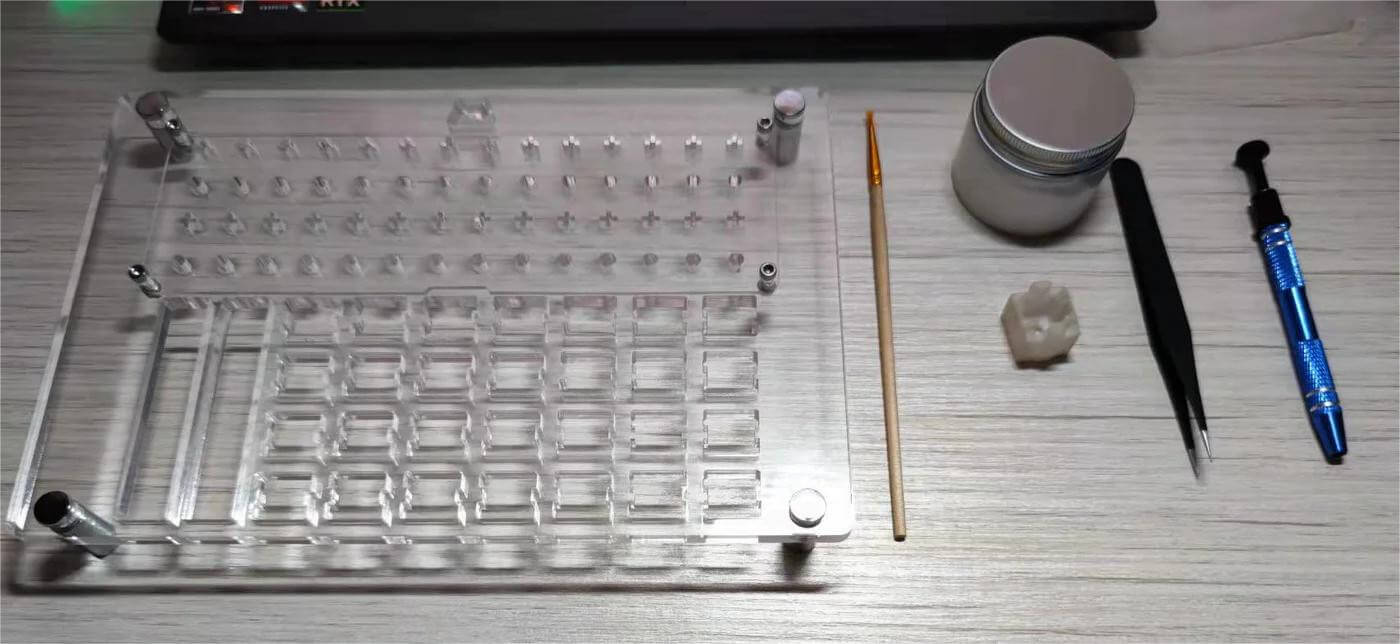

Since switch lubrication requires proper materials, here is a simple list of some auxiliary tools I usually use for switch lubing:

Essential tools: Lubricant oil and grease, brush, switch opener, and your hands.

Optional tools: Acrylic switch holder, tweezers, and a small pen for holding the switch stem.

2. Selection of Lubricants

Let's start by briefly explaining the difference between oil and grease. It's easy to understand that oil is a liquid, while grease is a solid.

When it comes to switch lubrication, we can divide it into lubricating the switch housing and the springs. I recommend using oil for the springs and either oil, grease, or a mixture of the two for the switch housing. However, it's generally advised not to use oil for the switch housing. Using a grease/oil mixture for the springs may cause them to stick, affecting their rebound. Fluid lubricants are more convenient for lubricating the springs, while a grease/oil mixture can achieve better sound dampening. It's not recommended to use oil for the switch housing because its higher fluidity compared to grease/oil mixtures can lead to uneven distribution. Additionally, using grease/oil mixtures helps achieve sound dampening. Most of the time, a grease/oil mixture is preferred.

Common lubricants include Krytox GPL104/105 for oil and Krytox GPL205/205G0, Tribosys 3204/3203 for grease/oil mixtures. As long as the lubricant is non-conductive, and doesn't significantly corrode metals and plastics, you can use any lubricant theoretically. However, I've even seen someone using peanut oil (not recommended and not a safe practice, please don't do it).

A proper lubrication amount should result in a transparent or slightly colored appearance after application. If the lubricant color is too prominent or the thickness is too noticeable, it can be considered excessive. Personally, I don't recommend excessive lubrication as it can affect the switch rebound and potentially create strange noises. In my opinion, excellent lubrication should maintain the normal rebound of the switch and enhance the inherent characteristics of the switch rather than making all switches sound the same. Excessive lubrication would only homogenize the sound of switches, but the purpose of lubrication is to enhance individual characteristics rather than erase them.

3. Spring Lubrication

Not only is there much debate about lubricating the switch itself, but even the methods for lubricating the spring are diverse. Some say you should lubricate the entire brush, others suggest lubricating just the ends, while some people claim that shaking the oil in a bag is sufficient. In my opinion, as long as you can eliminate the scraping sound of the spring, any method will do. Of course, if you don't like excessive rebound or a weak sound, a light lubrication to eliminate scraping is enough. Personally, I usually use the bag with oil method for lubrication, which is convenient for lazy people. However, after lubrication, you need to rub it open with your hands.

The common areas where spring noise is likely to occur are the contact between the upper end of the spring and the switch, the contact between the lower end and the switch base, and the scraping between the spring wires in the middle.

4. Lubrication for the switch Itself

(1) Understanding the Structure of the switch (Using MX Structure as an Example)

From top to bottom, the components of the switch are the switch base, spring, switch core, and switch top cover.

(2) Treatment of the switch Base

Typically, I recommend lubricating the two side rails (indicated by red arrows) on the switch base evenly. The amount of lubrication can vary based on personal preference.

If you need to eliminate the bottom-out sound, you can lubricate near the switch core's bottom shell pillar (indicated by a blue circle). However, I do not recommend this as it may result in an unpleasant bottom-out feeling.

Please avoid lubricating the inside of the switch core pillar (indicated by a green arrow) as it can cause unpleasant squelching sounds.

You can apply a slight lubrication to the small feet of the leaf spring indicated by the gray arrow but do not lubricate the area indicated by the yellow arrow, as it may lead to severe poor contact.

(3) Treatment of the Switch Core

It is evident that the areas where friction occurs with the lower cover are indicated by the red arrows on both sides, while the areas where friction occurs with the upper cover are indicated by the yellow arrows on both sides.

Lubricating both sides is sufficient. If you want to reduce the sound of the leaf spring, you can apply a slight lubrication to the red-colored small feet. If you want to reduce the impact sound when hitting the upper cover, you can lubricate the yellow areas.

If you want to eliminate the bottom-out sound, you can try lubricating the blue area (exercise caution when lubricating this part; it is not highly recommended as using too much lubricant or not applying it properly may result in a sticky feeling or strange sounds).

(4) Treatment of the Top Cover

From the image showing the contact between the switch core and the top cover, it is clear that the contact area is indicated by the red arrow.

If you want to reduce the sound of the switch core hitting the upper cover, you can lubricate the red area.

The above is a rough summary of my personal experience and suggestions for lubricating the switch. If there are any omissions, please kindly point them out and provide your valuable input. I appreciate your guidance and feedback.

Leave a comment

All blog comments are checked prior to publishing